Phase30 Rim

Lighter format / all mountain / trail riding

The PHASE30 mirrors our BA30 profile but in a lighter format that suits all mountain and trail riding conditions.

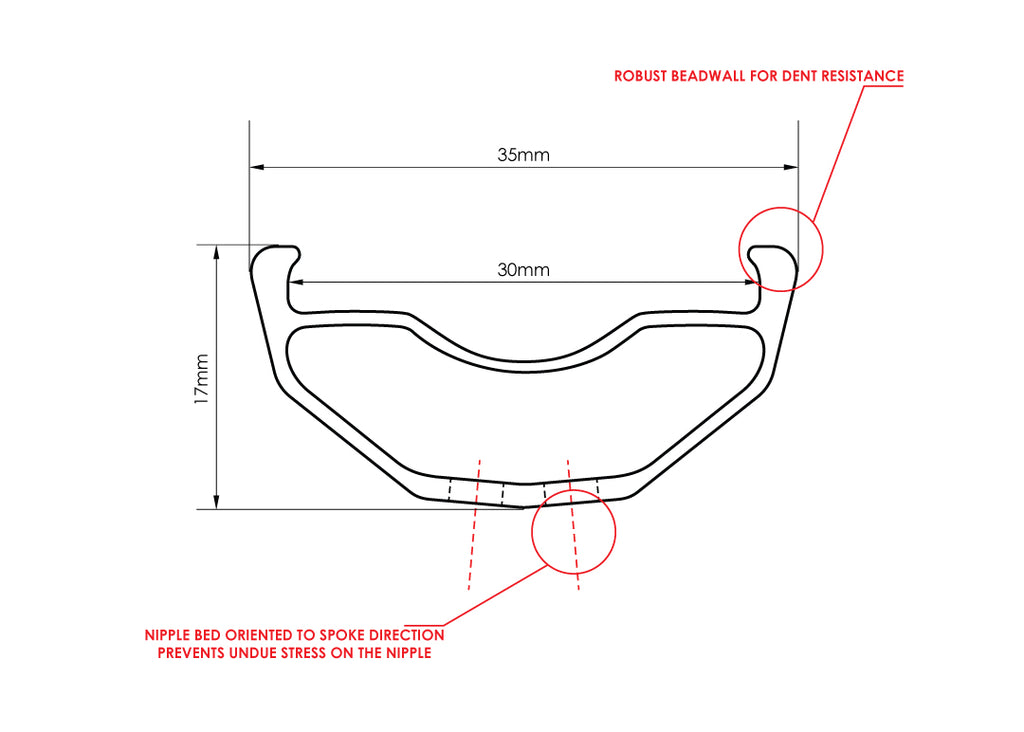

This is a high quality alloy rim that is tougher than most with added protection at the bead-walls for impact resistance and reduced sidewall cuts. The nipple/spoke bed is oriented to the spoke direction to reduce weakness caused by bend in the spoke at the nipple hole. The PHASE30 is made with premium alloy, extruded and carefully formed for consistent shape. It is then fusion welded and ground for a strong precise finish. Our fusion welding system leaves a perfect seamless joint that becomes the strongest section of the rim ensuring that your rim won’t split at the seam if you have an impact there.

Finish // Fusion welded seam-ground finish

Profile // Internal bracing profile / Impact resistant design

Tubeless // Tubeless Ready

Rim Weight // 27.5: 545g / 29: 584g

Internal Width // 30mm

Valve // Presta

Max Tire Pressure 2.4" // 45PSI

Max Tire Pressure 2.8" // 30PSI

Max Spoke Tension // 125KgF

Build Info // 27.5" ERD: 566mm / 29" ERD: 604mm

Hole Count // 32